Battery Type/'s

-Flooded Lead Acid,When testing batteries in the e-ride vehicle, it is important to test all batteries. Proper performance of the vehicle depends on all batteries being in good condition. Testing will determine if one (or more) of the batteries needs to be replaced.

A. The

preferred testing procedure is to use the Lester Electrical 72 Volt Battery Discharge

Unit (Model 25680). This instrument puts a known discharge load (75 Amps) on the

battery pack until the battery pack reaches 63volts. A timer incorporated into the

discharger measures the time needed to reach that voltage level.

1. First

refer to discharge unit operating instructions to fully understand the safety

and operation of the unit.

2. Turn

off the main battery disconnect.

3. Remove

all access panels to the battery pack. (see section 2.2.1)

4. Hook

up the negative cable clamp of the discharger to B- of the battery pack.

5. Hook

up the positive cable clamp of the discharger to B+ of the battery pack.

6. Run

discharger as described in the dischargers operating instructions.

7. When

the discharger is running its test, randomly test each battery sequentially in

the pack individually with a multi-meter and record the readings.

8. The

discharger will draw constant amperage of 80 amps. It takes 90-120 charge

cycles to achieve full battery capacity.

A new seasoned battery pack operating at 80°F (26.7°C)

should have 112 AH of capacity. At this load the discharger should run 1 hour

24 minuets (84 mins).

9. If

discharge times are low, as described in the discharger instructions run the

test a second time right away. The discharger will operate for 3 more minuets

which gives you enough time to get a final individual battery voltage reading.

Compare individual battery voltages recorded.

The results of the test can

sometimes lead to several different conclusions about the battery pack and

require varied action. The following

goes over the results and the conclusions to be drawn from them:

1. If

discharge time was 80 minutes or longer the issue is usually not with the

batteries.

2. If

discharge times are low, compare individual battery voltages recorded. If any

battery shows a 0.4 volt or greater variance, that battery is bad or nearing

the end of its useful life and should be replaced. The voltage of a bad battery will drop more

rapidly near the end of the discharge than that of a good battery.

3. If

all batteries are within 0.30 volts of each other, but the discharge time is

low, the batteries are approaching the end of their life and the whole set will

have to be replaced.

4. Other

variables that need to be considered in this test is the battery temperature

and Cycle life. If battery temperature is below or above 80°F (26.7°C)

the overall capacity will lower or increase but the battery voltage should

still not vary 0.30 volts of each other. As for cycle life it takes 90-120

charge cycles to fully season the battery pack. Cycle cycles below this can

lower the capacity as much as 20%. In other words a new battery pack performs

to 80% its rated capacity.

B. If

the Lester Battery Discharge Unit is not available, an alternate battery test can

be done using a multimeter to perform a voltage test of each battery. The most

inexpensive way to perform this test is to use the vehicle’s drive system as

its load. Perform the test as follows:

1. Charge

the batteries until the charger shuts off.

2. Remove

all access panels to the battery pack. (see section 2.2.1)

3. Make

sure you have no loose components in the vehicle that could fall into the

battery tunnel.

4. It

will help to have two people to perform this test. One person to drive the vehicle and the other

person use the multimeter to measure and record the voltage.

5. It

is best to pick a course that is flat and long without many stops.

6. Record

what time the test started.

7. Check

the battery pack voltage every 10 minutes of driving. As soon as the battery pack voltage reaches

64 volts start measuring and recording each battery to the nearest 0.01 volt

until battery pack reaches 63 volts which is zero state of charge. At this point, record the time and the test

is complete.

The results of the test can

sometimes lead to several different conclusions about the battery pack and

require varied action. The following

goes over the results and the conclusions to be drawn from them:

1. If

discharge time was 80 minutes or longer the issue is usually not with the

batteries.

2. If

discharge times are low, compare individual battery voltages recorded in step 7

above. If any battery shows a 0.4 volt

or greater variance, that battery is bad or nearing the end of its useful life

and should be replaced. The voltage of a

bad battery will drop more rapidly near the end of the discharge than that of a

good battery.

3. If

all batteries are within 0.30 volts of each other, but the discharge time is

low, the batteries are approaching the end of their life and the whole set will

have to be replaced.

4. It

takes 90-120 charge cycles to achieve full battery capacity. A new seasoned battery pack should have 112

AH of capacity. On flat, even terrain a

stock vehicle draws about 85 amps per hour at 25 MPH giving you 80 minutes of

drive time. Totaling 33 miles per charge.

5. Other

variables that need to be considered in this test is the battery temperature,

cycle life and amp draw. If battery temperature is below or above 80°F (26.7°C)

the overall capacity will lower or increase but the battery voltage should still

not vary 0.30 volts of each other. As for cycle life it takes 90-120 charge

cycles to fully season the battery pack. Cycles below this can lower the

capacity as much as 20%. In other words a new battery pack performs to 80% its

rated capacity. And as for amp draw this requires higher expensive equipment to

be done accurately but what to consider here is if you are on a hilly terrain

the vehicle will draw more lowing your overall run time.

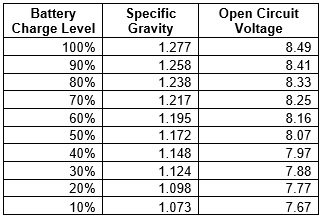

Hydrometer Test

A third option for battery testing is to perform a specific gravity test of the battery electrolyte using a hydrometer. A hydrometer measures the specific gravity. An increase in the specific gravity correlates directly to an increase in battery state of charge. A fully charged battery should read between 1.250 and 1.280 at 80°F. Never add acid to a battery to obtain a higher specific gravity.

Performing the hydrometer test

1. Be

sure the batteries have sufficient water to cover the plates by approximately

1/2” and are fully charged prior to beginning the test. If distilled water must be added, recharge

the batteries before performing the hydrometer test.

2. Flip

open the cover of the battery filling float assembly. Locate the white plug under the cover and

remove it. These holes should provide

enough access to be able to perform all tests.

3. Using

a battery thermometer, record the electrolyte temperature of one of the middle

cells.

4. Squeeze

the rubber bulb of the hydrometer and insert it into the cell of the

battery. Slowly release the bulb,

drawing the electrolyte into the hydrometer. Fill and drain the hydro meter two

to four times before drawing a sample.

5. When

the hydrometer float rises off the bottom, adjust the electrolyte level so the

float floats freely from the bottom but does not strike the top of the glass

tube. Remove the hydrometer from the cell and release the pressure from the

bulb.

6. Hold

the hydrometer vertically, ensuring that the float is not contacting the sides

of the barrel. Hold the hydrometer at

eye level and read the scale at the level of the electrolyte.

7. Record

the reading.

8. Return

the electrolyte to the cell from which it was taken. Close float cap and

replace the white plug.

9. Repeat

steps 2-8 on all cells.

10. Temperature correct each cell reading. The readings obtained as described above must be corrected for temperature. Temperature correct each cell reading. For each 10°F (5.5°C) above 80°F (26.7°C) add 0.004 to the specific gravity reading. For each 10°F (5.5°C) below 80°F (26.7°C) subtract 0.004 from the specific gravity reading.

11. The specific

gravity of all battery cells should be 1.277 + or - 0.007. If low cell readings

exist (see chart below), charge battery and take specific gravity readings again.

12. If specific gravity of any cells remains low after complete charging, battery should be replaced.