Drive System/'s

ALL DrivesBattery Type/'s

-Lithum 200AH 3.3KW Charger-Lithum 200AH 3.3KW Charger

HVAC System/'s

All HVACManufacture Dates

Between 07/13/2015 Thru 12/31/2024

Receiving/Inspection/Test of new lithium cells:

Entire battery pack of lithium cells are shipped

to you typically via full freight/semi-truck. Truck will not have a drop gate.

So if you do not have a loading dock or way or unloading pallet from trailer

the pallet packaging can be opened up and each box can be hand lifted off

truck. For a complete battery pack you will receive 12 boxes. Each box will

contain a bundle of 4 lithium cells each. Totaling 48 cells.

Shortly after receiving

cells you will want to remove the purple caps and do a simple voltage check of

each of the 24 cells. Nothing needs to be disconnected. Just prop positive and

negative of each cell with a volt meter. Each cell is typically 3.2 volts. They

should all read fairly the same. 2.5V is 0% state of charge. Make sure none are

below the 2.5 volts or large deviation from the rest of the cells. If so please

contact us about the issue right away. Low voltage readings after cells are

installed into the vehicle can be caused by incorrect wiring. So issue needs to

be reported shortly after receiving cells.

Packs are shipped

in the incorrect cell configuration for the 200AH lithium pack. The 200AH pack

uses a series/parallel configuration. Packs are shipped for the 100AH configuration

which is series only configuration. So in order to place them in the correct configuration

all jumpers from each pack need to be removed. The pack if bound together with

straps and aluminum plates on each end. On one end you will find screws. These

screws need to be removed so pack will open up. The two center cells need to be

turned 180 degrees individually. End result they would be the exact same orientation

as your current cells. Pack will need to be clamped back together to get the

pack screwed back together. But read though entire instructions below before clamping

back together the cells. There are thermostats in 4 of the packs. Options on what

you can do are listed below. Also when installing jumpers you need to order an

additional qty. 96 of part# U5635A-1N or these need to be removed from your old

pack. For the entire pack this is typically a 2 hour job for a skilled person

and up to 8 hour job for a newbie.

Battery disconnect:

Shut off the main battery disconnect located in

the front right wheel well. Also make sure front battery charger inlet plug is

disconnected from the main power grid.

Unplug battery management system (BMS):

Under the driver's seat you will find a black or

silver colored box screwed to the side of the battery tunnel. The long

connector with multiple orange and red wires plugged into the BMS must be

unplugged before disconnecting any of the connections within the battery pack.

If not done so damage to the BMS is highly possible.

Open up the center battery tunnel:

The battery pack is accessed by setting the

parking brake handle. Higher the better. Lift up on the center arm rest pad and

move it back as far as you can. Grab the center console and pull back. Center

console has the cup holders attached to it. At the rear of the center console

are heater hoses that slide off and some electrical connectors that need to be

unplugged. Now you should be able to remove the center console from the cab of

the vehicle. (Note if your vehicle is equipped with fuel fired heater center

console does not exist) Lift up on the center tunnel cover and remove from the cab.

It is just velcroed down. If 4 door model entire pack will be exposed. But if 2

door model you will need to remove the access panel on the center front of the

flatbed to access the rear cells. To remove access panel use a heavy flat screw

driver to rotate the ¼ turn latches. Panel will then lift out of way.

Removal of lithium cells:

In the battery tunnel you will find. 48 lithium

cells. Each cell has a purple plastic cap that just lifts off. In order to

remove all the caps the 5 battery hold down straps need to be removed. This is

done by unbolting them. The bolt that holds them down is a J-bolt at the bottom

and will not move. After removal of black plastic hold downs the J-bolts become

loose so make sure they don’t come in contact with the battery pack

connections.

Battery pack

consists of two rows. 24 cells down the driver’s side or 6 packs of 4 cells

each and 24 cells down the passenger’s side also 6 packs of 4 cells each. Note

that there is a small wire connecting to each parallel connected cells. Some

have one wire others have 2 wires. These small wires must go back on at the

exact same post. I cannot address this enough. If not done so damage can occur

to the BMS, vehicle will not charge or turn on and if not corrected over a day

or so the charge can be draw out of the incorrect wired cell. Resulting in low

voltage of one cell unbalancing the pack. 99% of calls we get receive are a

result of this issue. Each of these small wires have a number stamped on them

indicating which cell they go to. The drivers side rear two cells (most

negative) is cell #1. They increment up every other cell as you move forward.

The front two cells on the driver’s side is cell #12. Then it crosses over to

the front two cells on the passenger’s side is cell #13. They increment up every

other cell as you move towards the rear of the vehicle. The passenger’s side

rear two cells (most positive) is #24.

If it helps take

a picture of the pack prior to disassemble giving you something to look back on

for reference.

At the front you will find a buss bar jumper connecting

each of the rows together. Take and remove this jumper by removing the 4 screws

from each end of it. Note that each jumper is 4 layers thick. Next take and

remove the positive battery cable on the passenger’s side rear. Then the negative

battery cable from the driver’s side rear. Next you will find jumpers going

between each of the battery packs. These would have been hidden under the

plastic hold downs removed earlier. The jumpers within the 4 cell packs does

not need to be removed.

At this point each of the 4 pack cells can be

lifted out. You will find at the end of four of the packs they have black wires

going in the sides if them. These are thermostats. Any unit built prior to 2024

these thermostats went in between the aluminum plates and the cell. The

aluminum ends were milled to allow room for the thermostats. The new battery

packs you have are not milled for the thermostat. To remove the thermostats

from the old packs find the end of the pack that has screws. One end is rivets

other end is screws. Remove these screws and the pack will open up to where you

can remove the thermostats. First off I should mention they are important and must

be reinstalled. You have two options to install them into the new battery

packs. One is to reuse the aluminum ends from the old pack onto the new pack.

If done this way it does require some clamping. The straps are tight. Second

option is to stick them to the outside of the aluminum plate. Make sure to keep

them in the same location. Such as the middle of the cell. Typically a good

option is aluminum tape used in duct work or even better a tar tape used in

gutter repairs. Clean aluminum and then adhere to tape with thermostats in

middle of tape. Make sure tape is adhered well.

Installation of lithium cells:

Note at the bottom of the battery pack you will

find the battery warmer. Make sure it is visually good. Under it is an

insulation typically white. Each of these are just laying at the bottom.

Removal would be the reversal of installation

with a few notes.

·

At each of the positive

and negative posts of the 4 cell pack you will find the 4 screws holding down a

plastic spacer. These spacers are removed and discarded.

·

Each of the 4 screws are

just hand tight. Paperwork with cells gives the torque spec if you require one.

In the event you do strip threads there is a heli-coil insert that can be

removed and have a new one installed.

·

More than likely with your

new cells you receive new jumpers. Make sure each of them consists of 4 jumpers

stacked together.

· As noted before make sure to connect the correct small wires to each cell. Very important.

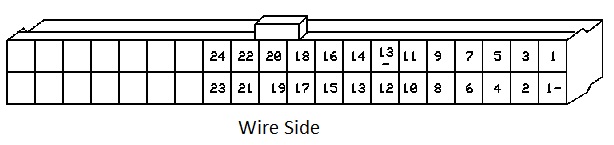

To make sure you have the small cell wires connected correctly you can perform a voltage test at the cell tap connector that was unplugged at the BMS under driver's seat. Diagram of this connector is below. Prior to plugging in connector take a voltage meter set to read DC voltage. During this entire test you will place negative test lead on pin 1- which is a black wire in the corner. Next place the positive test lead on pin 1. Meter should read the voltage of cell #1 which would be roughly 3.2 volts. Move positive test lead to pin #2 and voltage will increase roughly 3.2 volts over the last reading so in this case 6.4 volts. Keep incrementing up each pin#. Each one should increase the roughly 3.2 volts. When you get to 13- this is a ground going to pin #13 so it will not increase on this reading. Will read the same of pin #12. At the end pin #24 you will read full pack voltage of roughly 80 volts. If any of the readings say go up 6 volts or go down then you have wires wired incorrectly at the cells. Need to source which ones are incorrect, fix and then retest.

After all is connected correctly at this point you

can plug back in the battery management system under the driver’s seat and turn

back on the main battery disconnect switch. Vehicle will need to be plugged in

to power up. After plugging in the battery charger should turn on. Typically the

fan would be running. Also if vehicle turns on you can press and hold up button

on dash display which shows battery information. The pack current should be

showing negative such as -14.8 if charging on 120VAC. If so you should be good

to go. Do note that in this same screen it does show pack cycles. It is a good

idea to note this down somewhere to keep to you know how many cycles you got on

your battery pack.

Other option is if you have the diagnostic cable and a laptop you can reset the pack cycles back to 0. Items required for this is part# U5665A-N and your own laptop. When purchase is made you will be e-mailed a link to download the software. I will not get into the nitty gritty of installing program in this forum. But after connecting to vehicle click on file on upper left corner and select “Reset Historical Battery Data”. Pack cycles should now be 0.