The Topic Is For

Battery Type/'s

-Lithum 100AH 3.3KW Charger-Lithum 200AH 3.3KW Charger

-Lithum 100AH 6.6KW Charger

-Lithum 200AH 3.3KW Charger

Manufacture Dates

Between 08/07/2014 Thru 12/31/2024

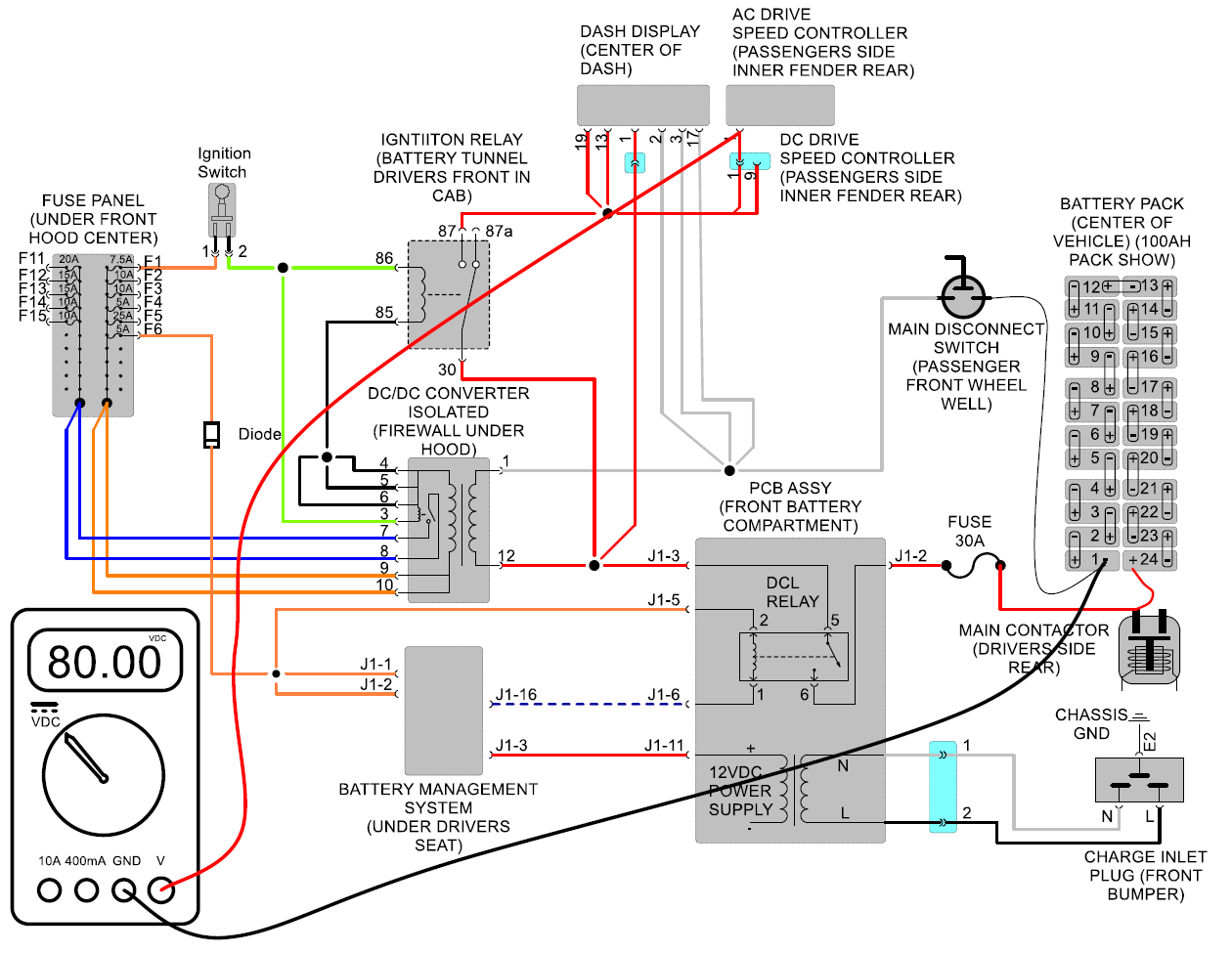

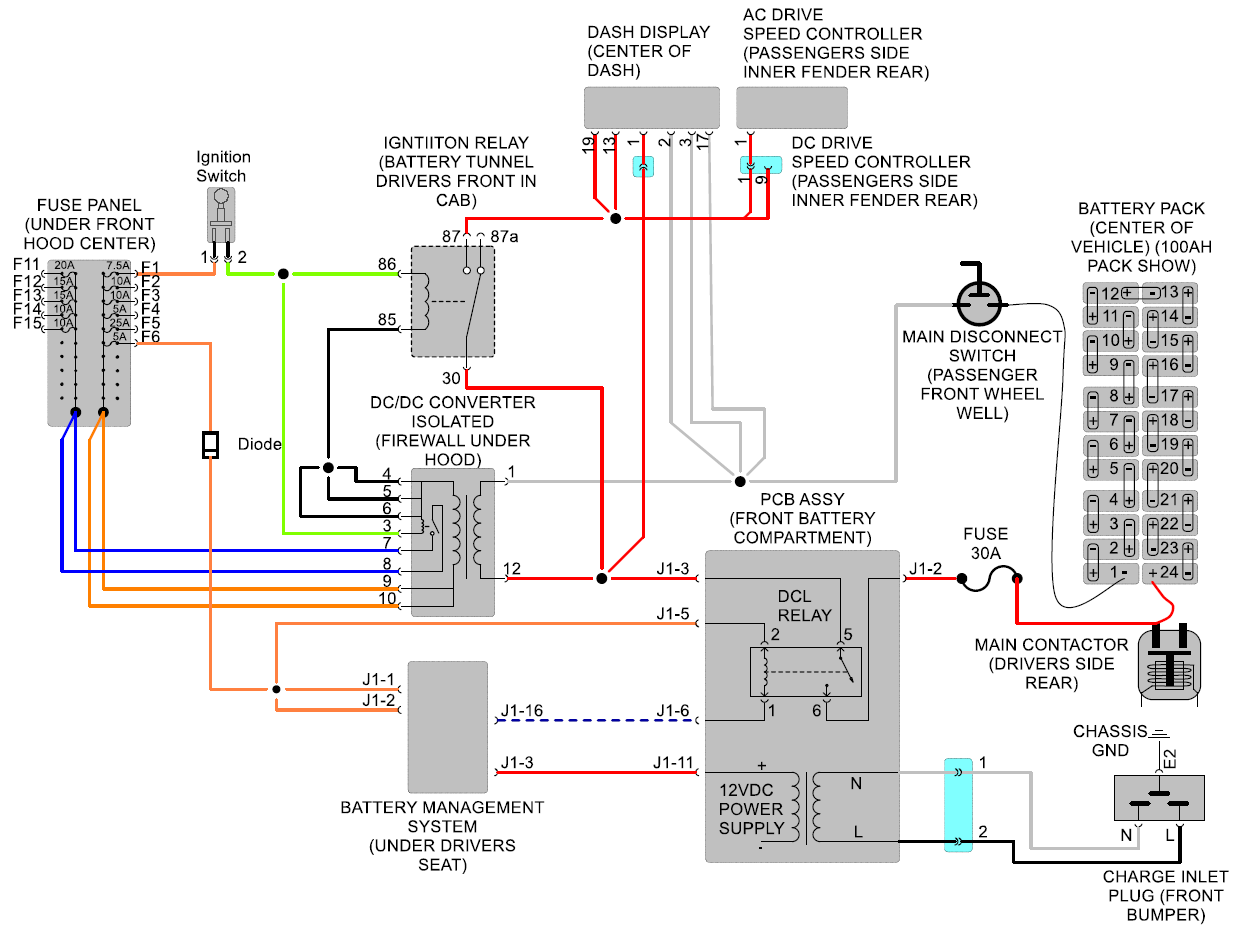

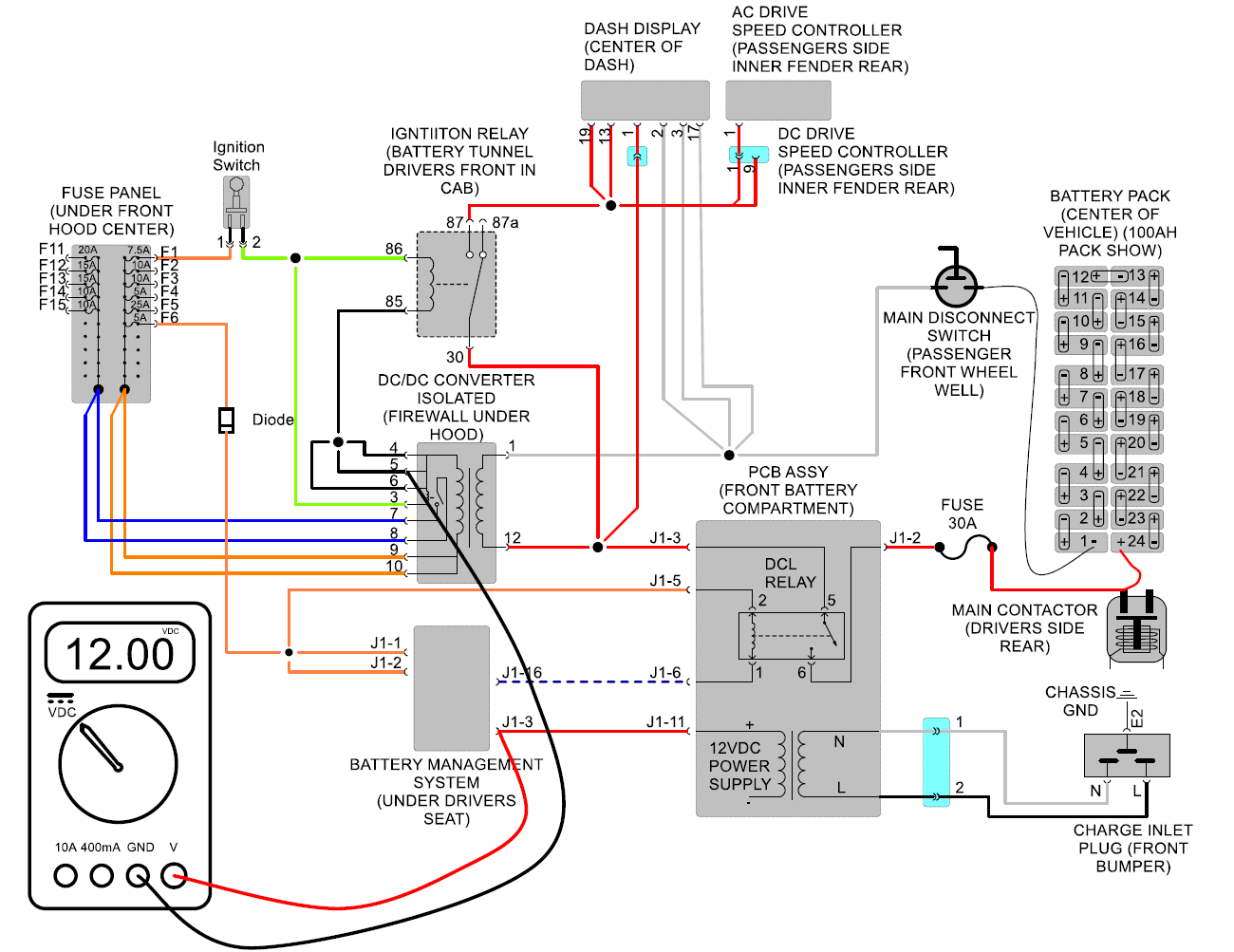

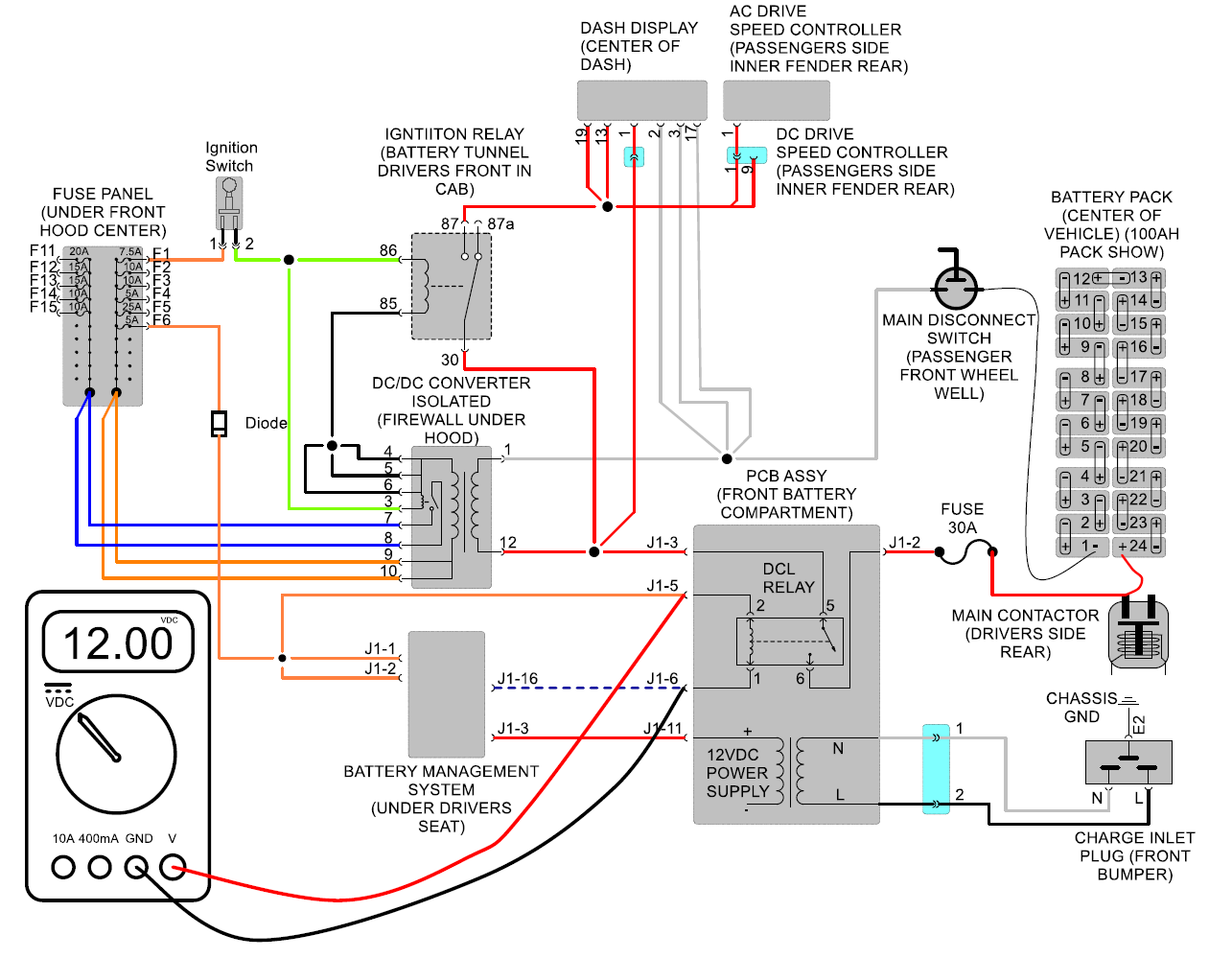

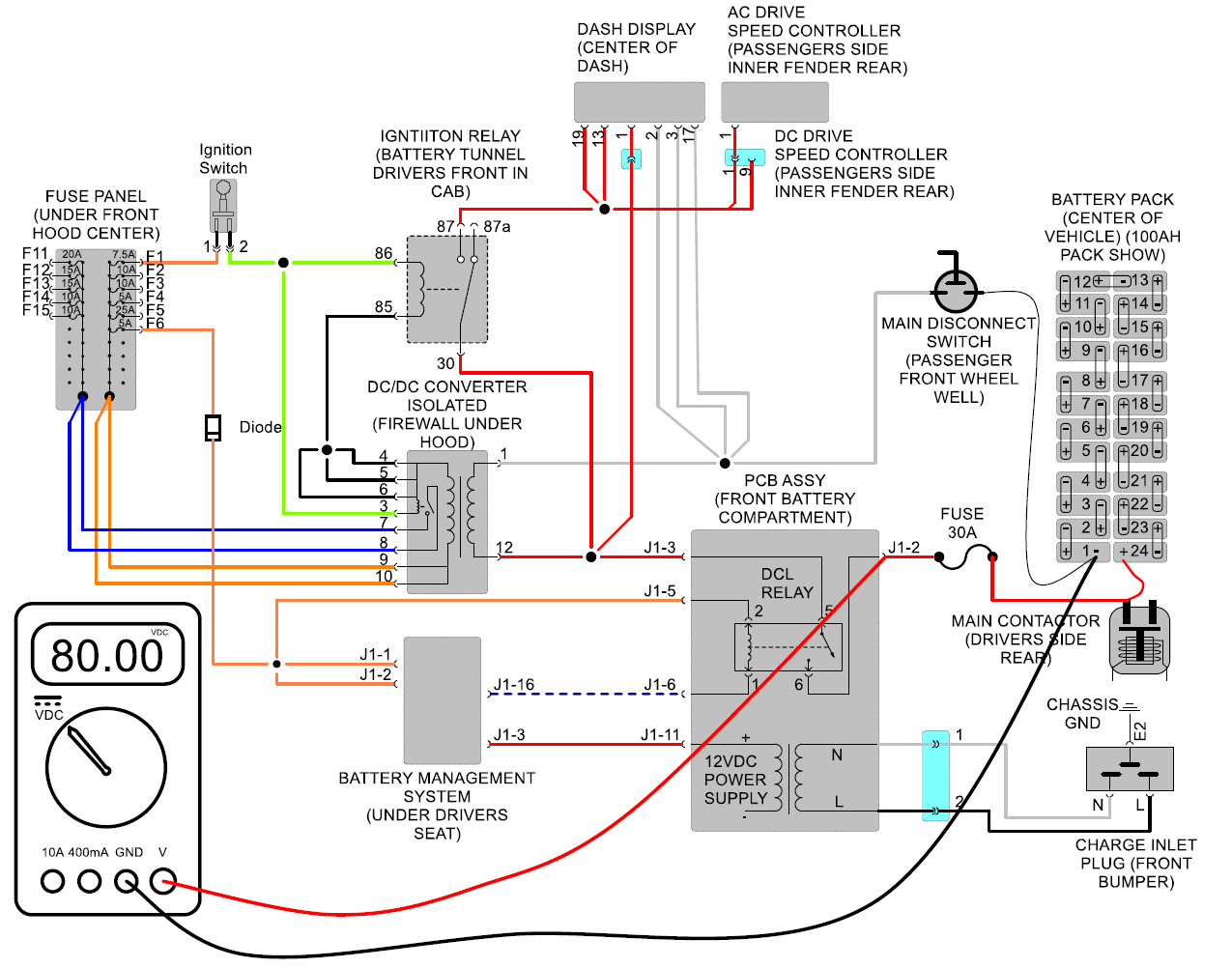

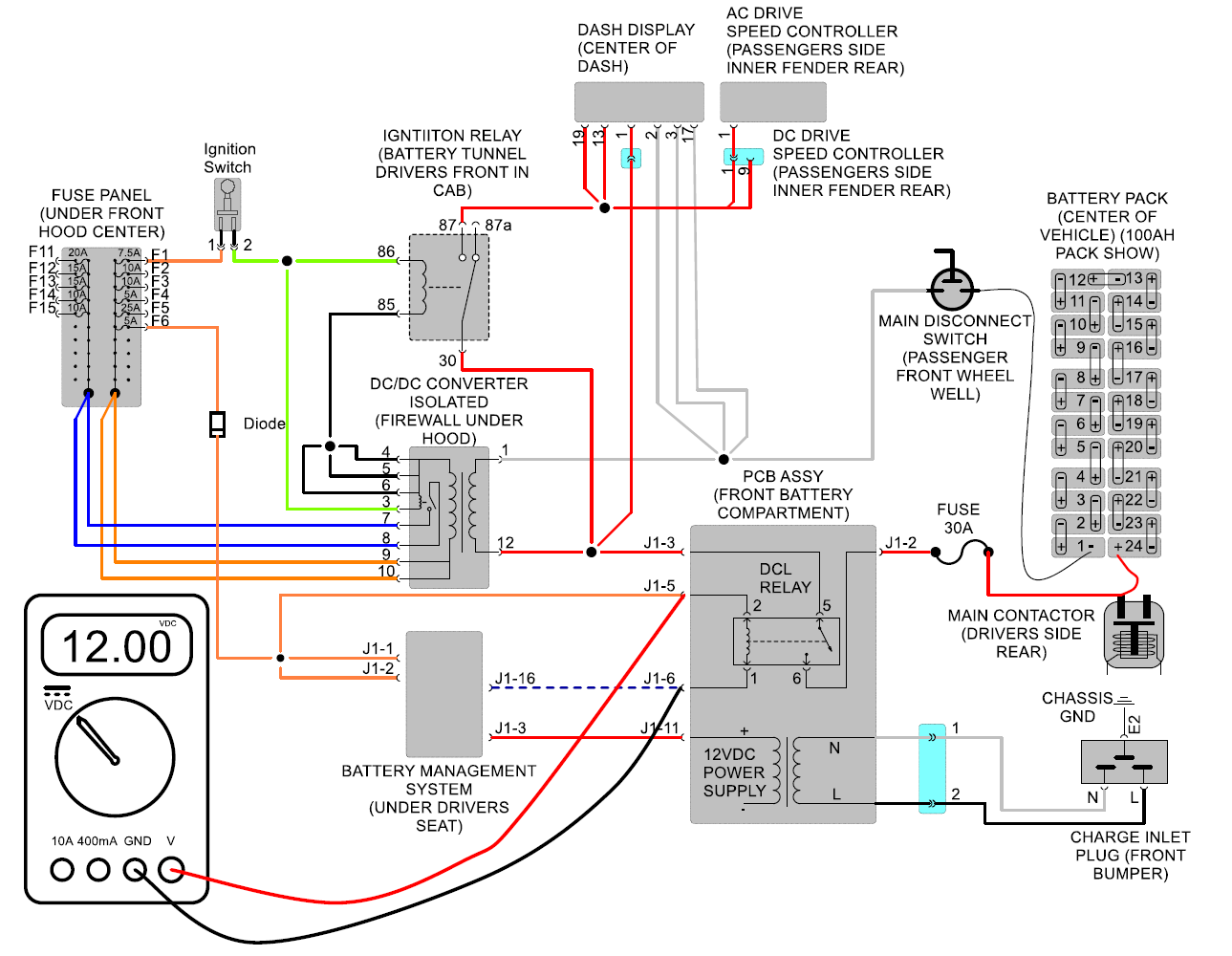

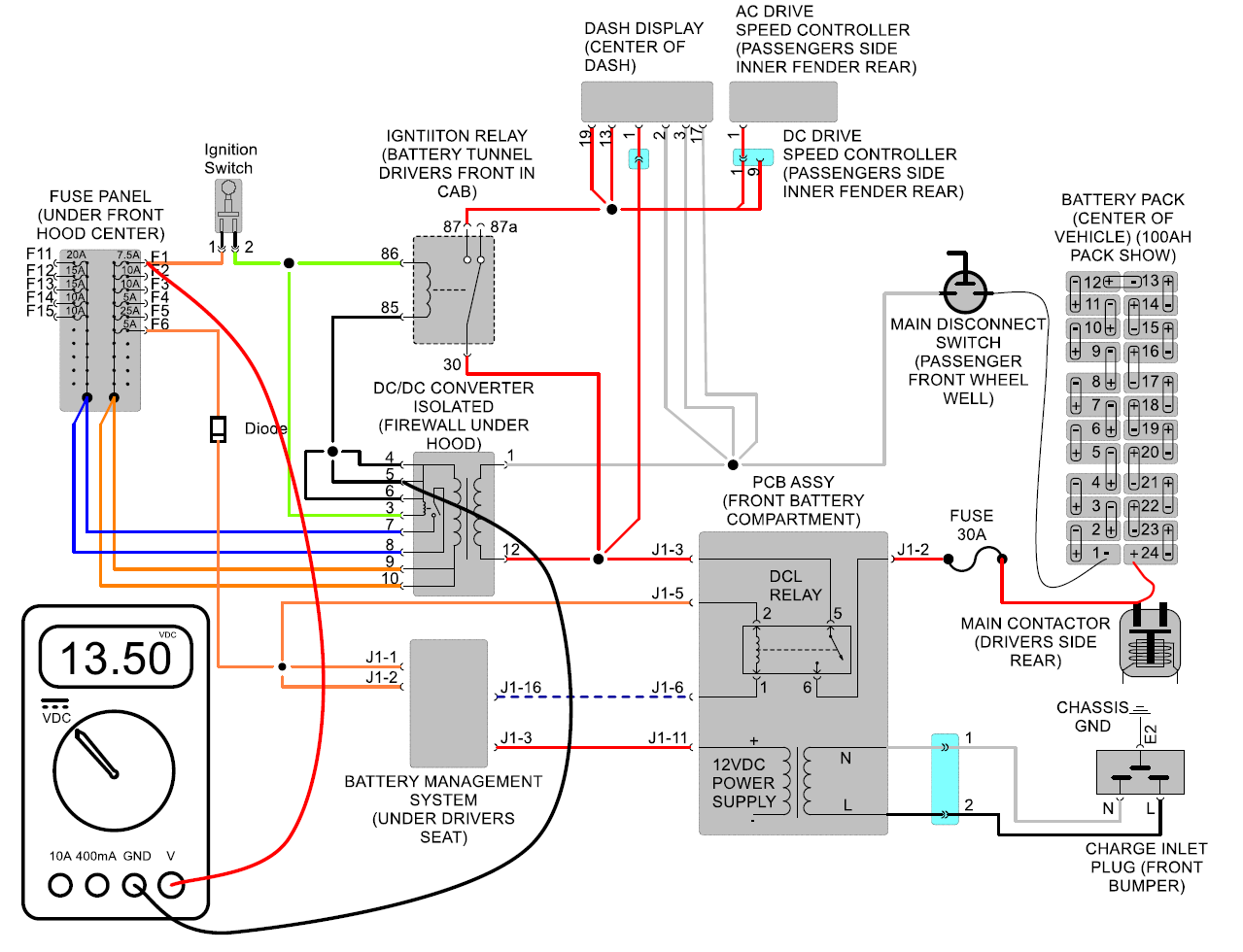

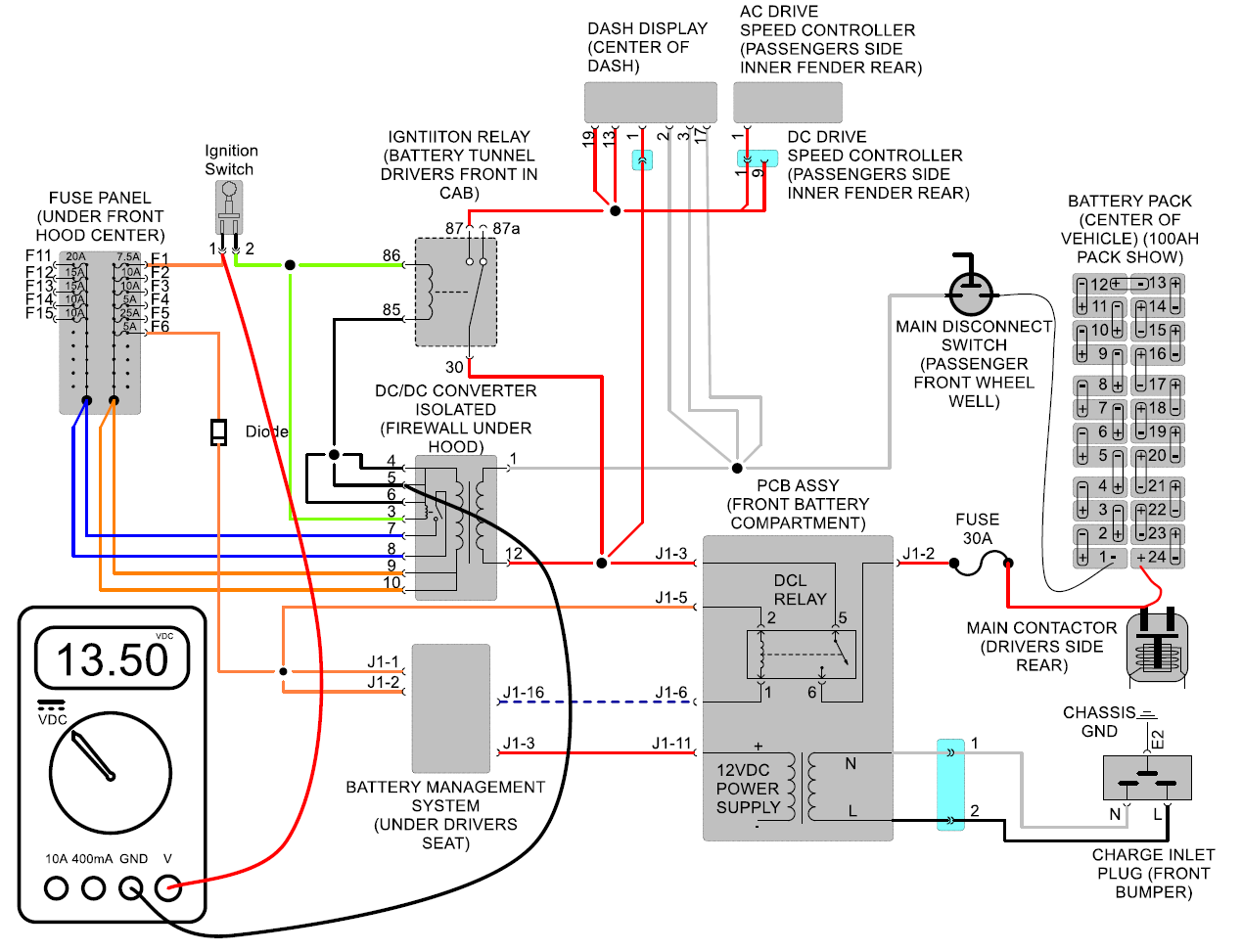

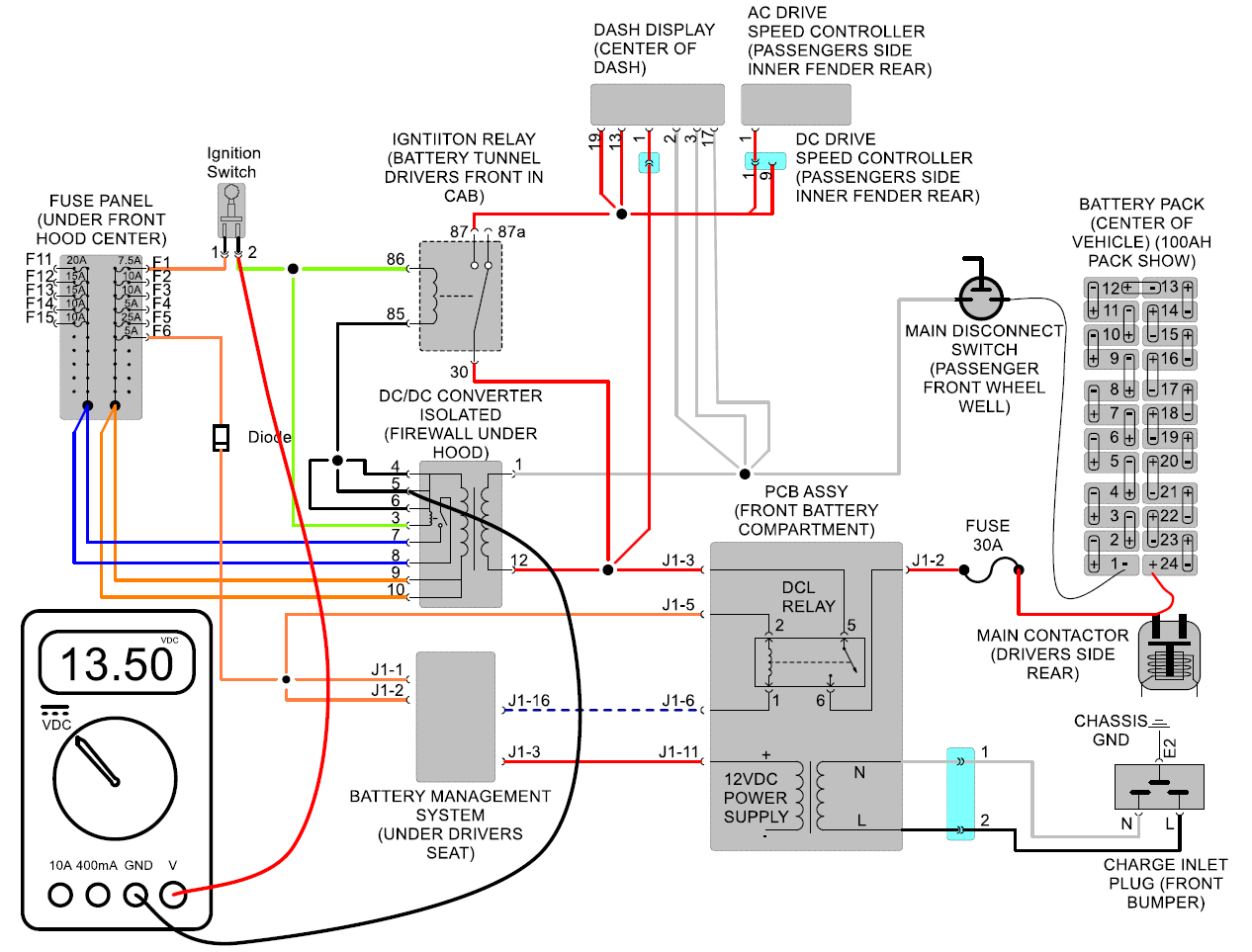

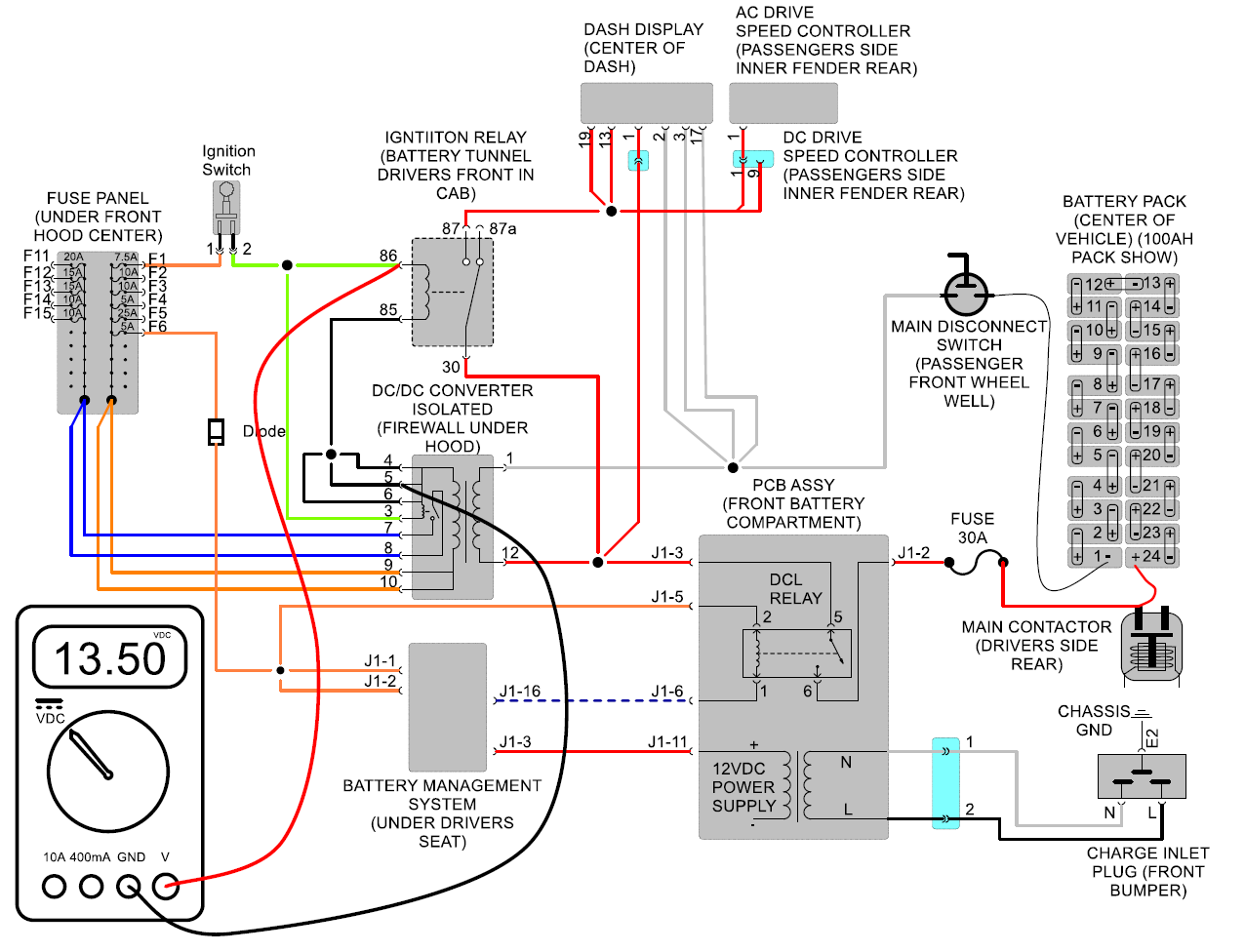

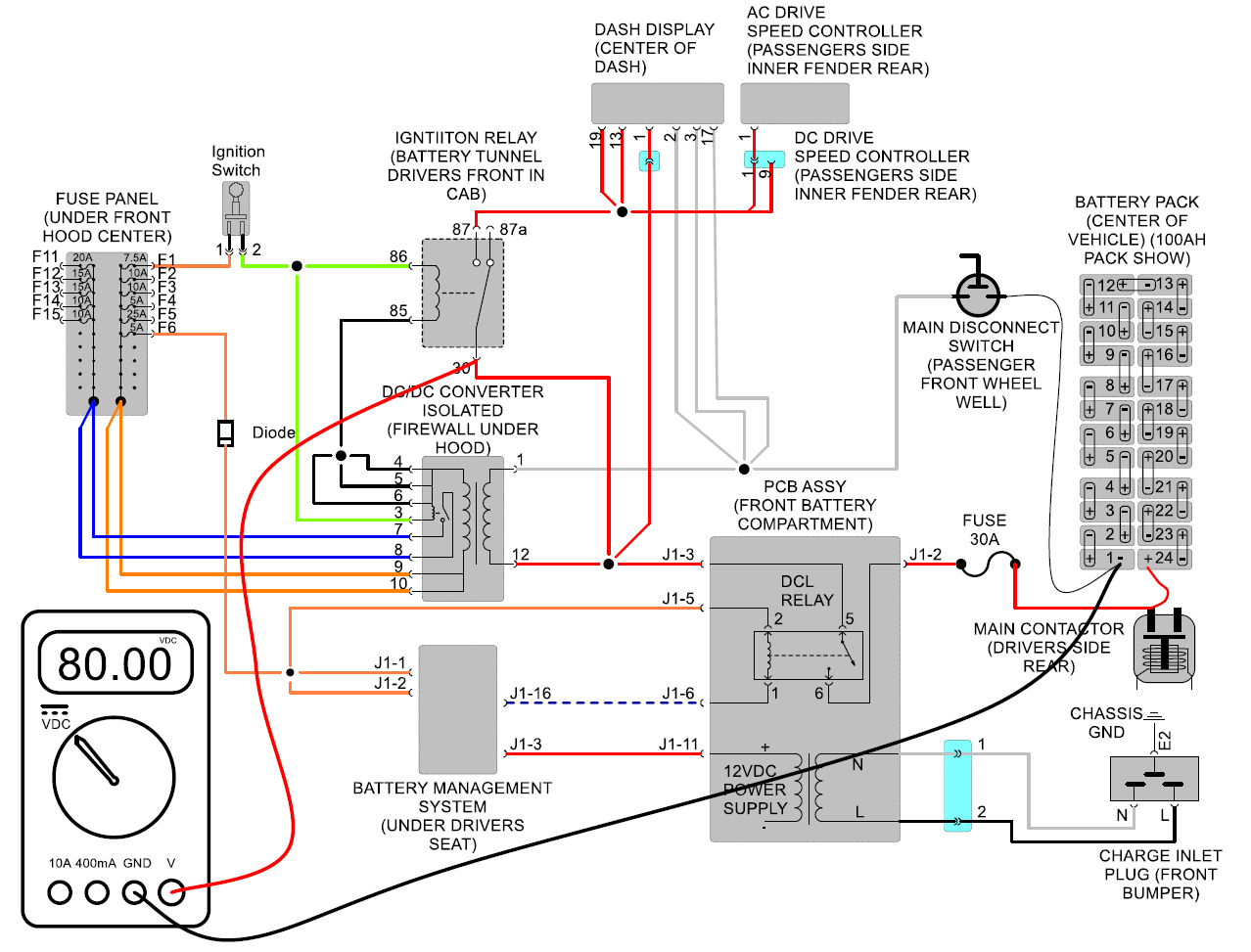

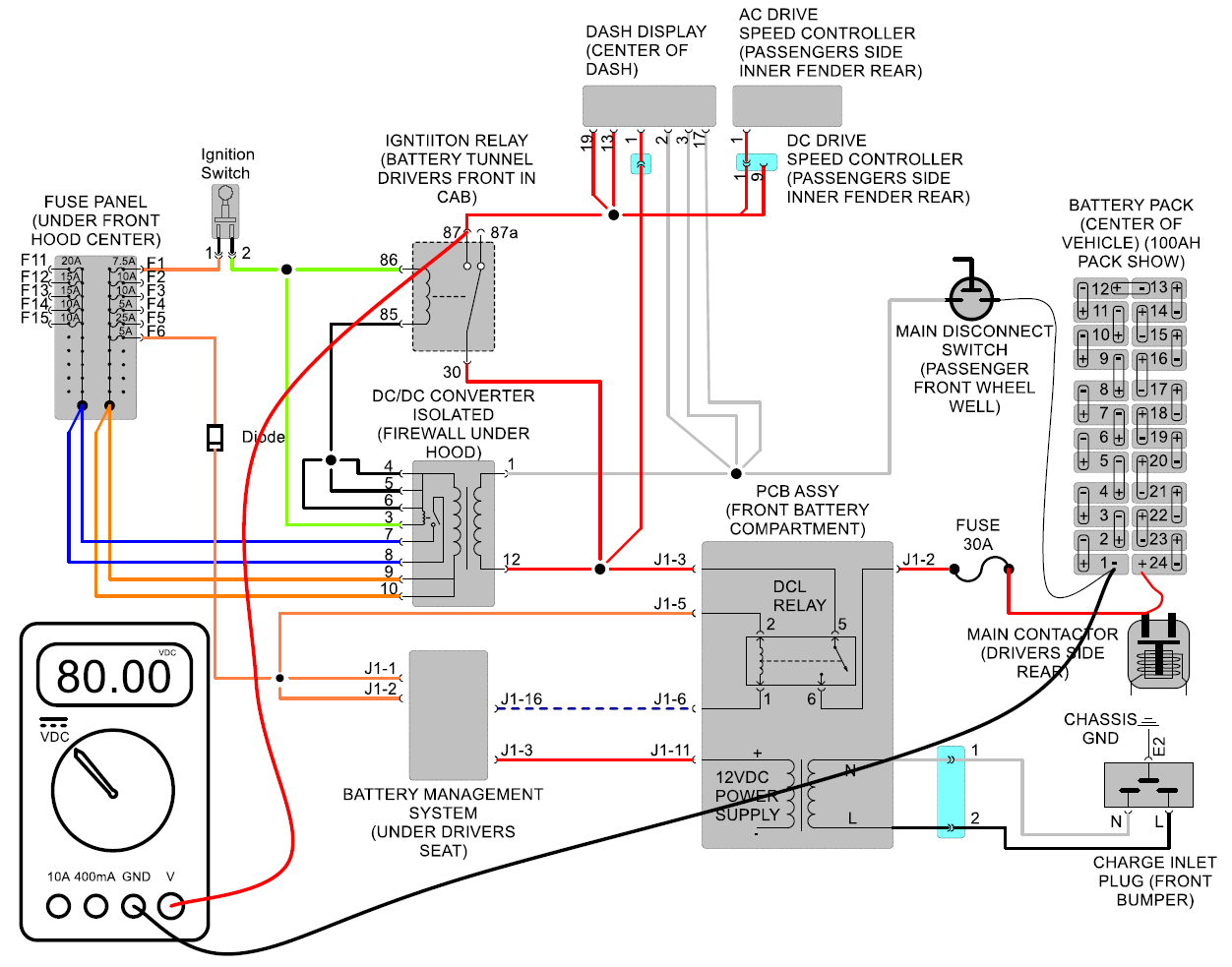

Ignition Circuit Wiring diagram

Test #1

Measure voltage between pin#1 pin#12 of DC/DC converter 12 pin connector. Connector

can be unplugged for this test

but have the front bumper plugged in like

as if you were charging vehicle. Should

measure battery pack voltage which is typically about 80 volts DC.

If so, see test #2.

If not see test #1-2

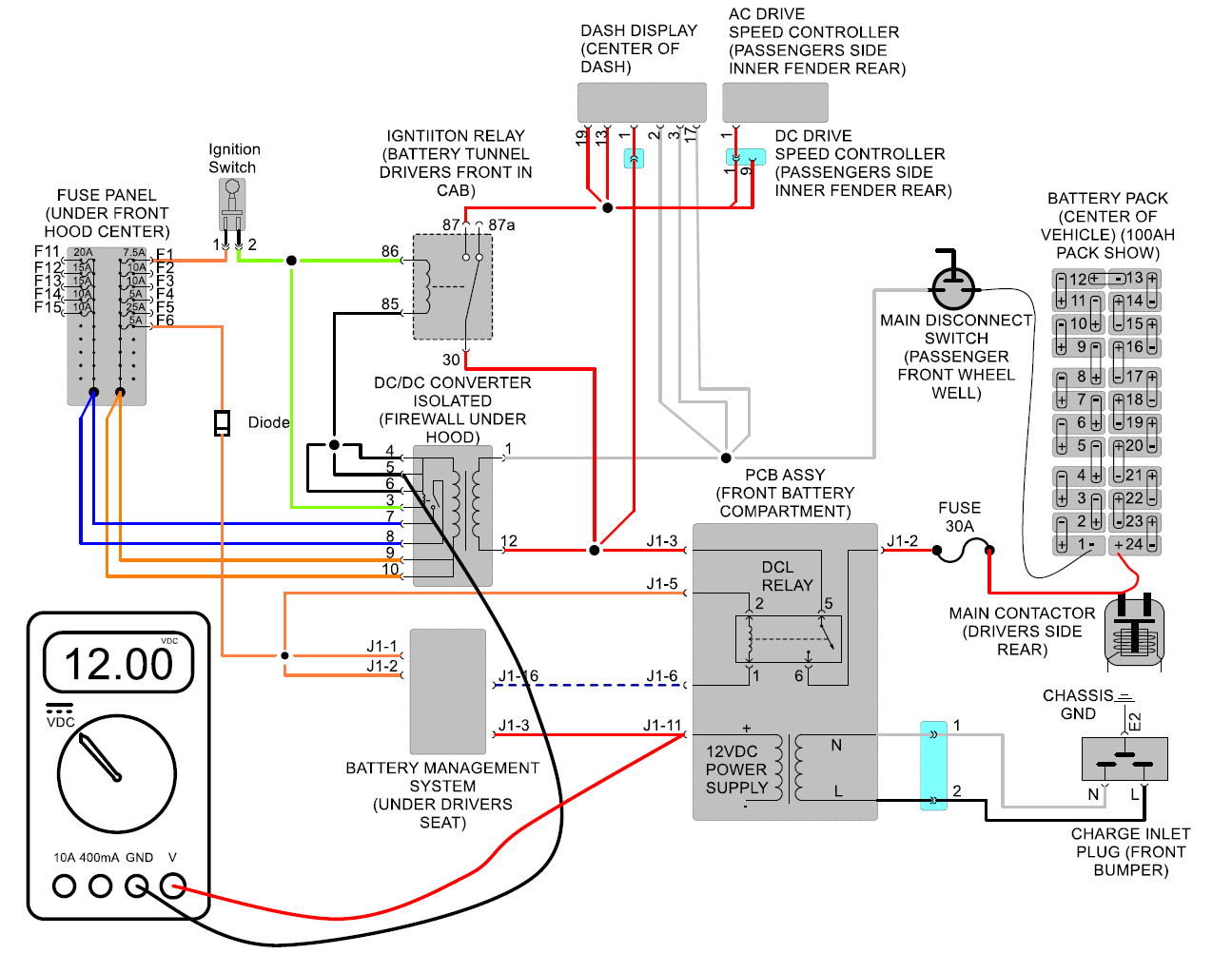

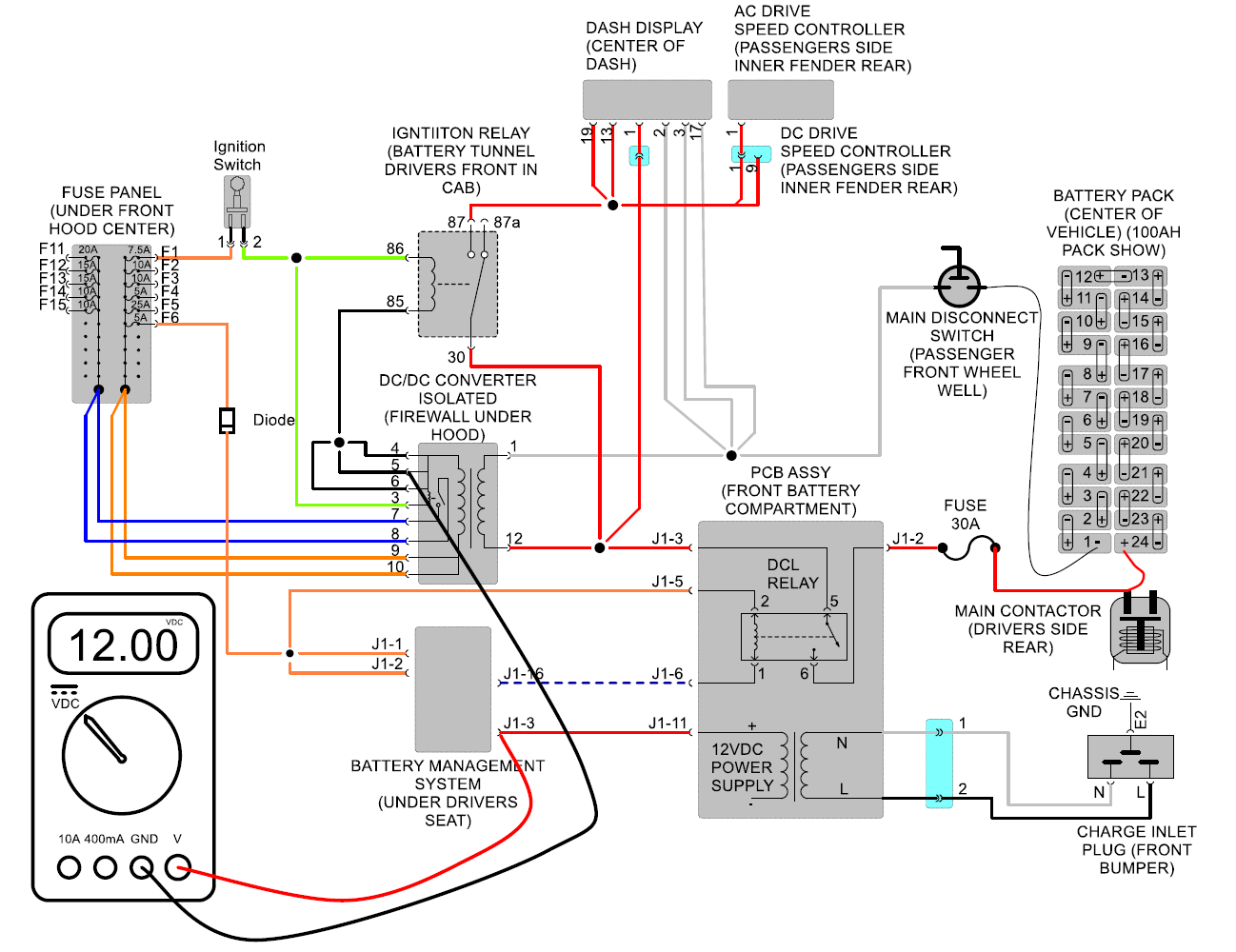

Test #1-2

Measure voltage between pin #4, 5 or 6 of DC/DC converter 12 pin connector (Connector must

be plugged in for this test) or any

small black wire at the 15-pin connector

going to center console and pin #11 of PCB assy. Have vehicle plugged in at the front

bumper as if it were

charging. Also, connector must remain

plugged into the PCB assy. for this test. You should measure about 12 volts

DC.

If so, see test #1-3

If not see test #1-2-2

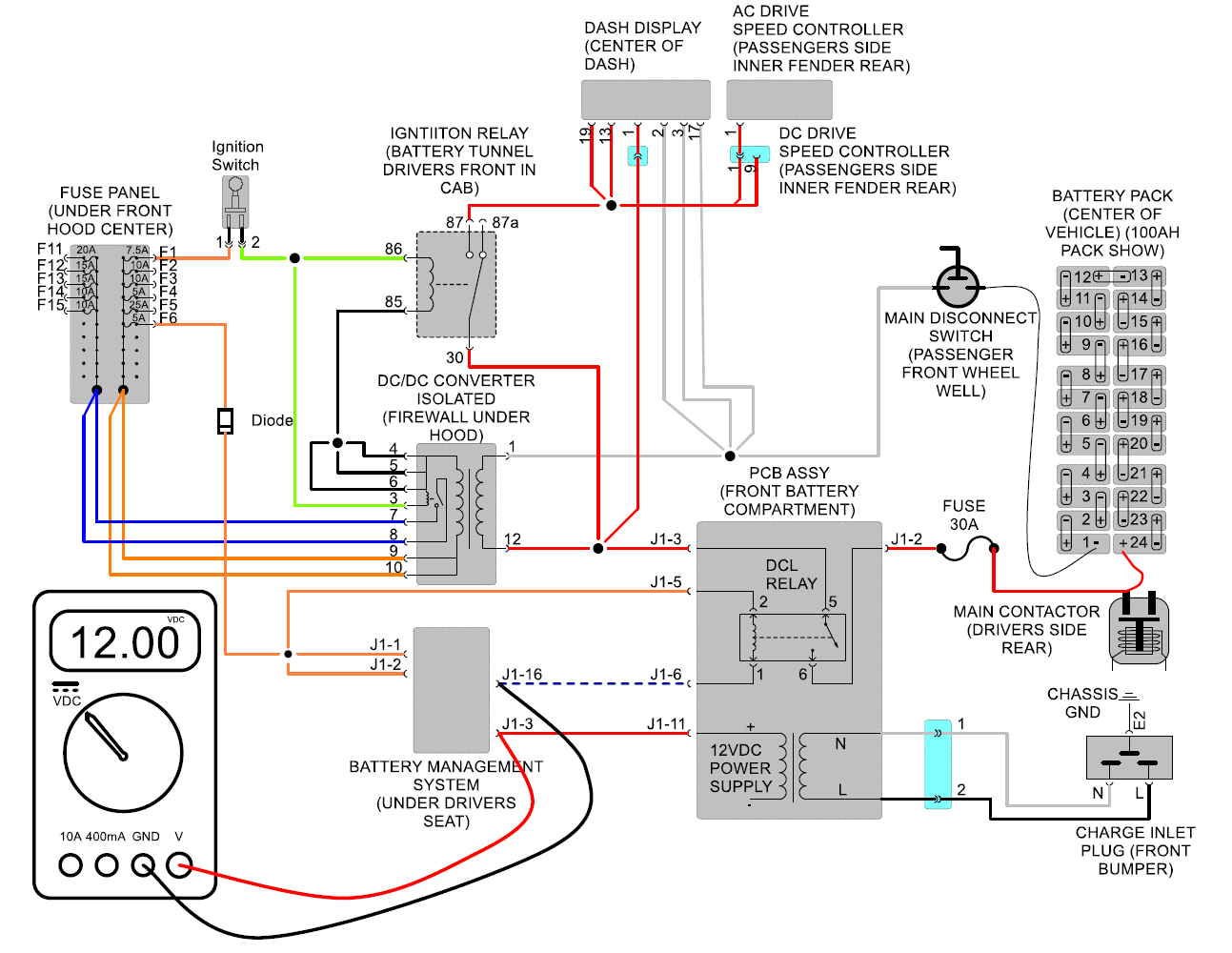

Test #1-2-2

At the battery management system located under the drivers seat. Locate the main I/O

connector which is white and has 26 pin

locations. Measure voltage between pin #3

and pin #4, 5 or 6 of DC/DC converter 12 pin

connector (Connector must be plugged in for this test) or any small black wire at the 15

pin connector going to center console. Have

vehicle plugged in at the front bumper as

if it were charging. Also connector must remain plugged into the BMS for this

test. You should measure about 12 volts DC.

If so, see test #1-3

If not more than likely the battery management system has an internal fault the DCL relay will not

close and this fault must be corrected. Or also see

test #1-2-3

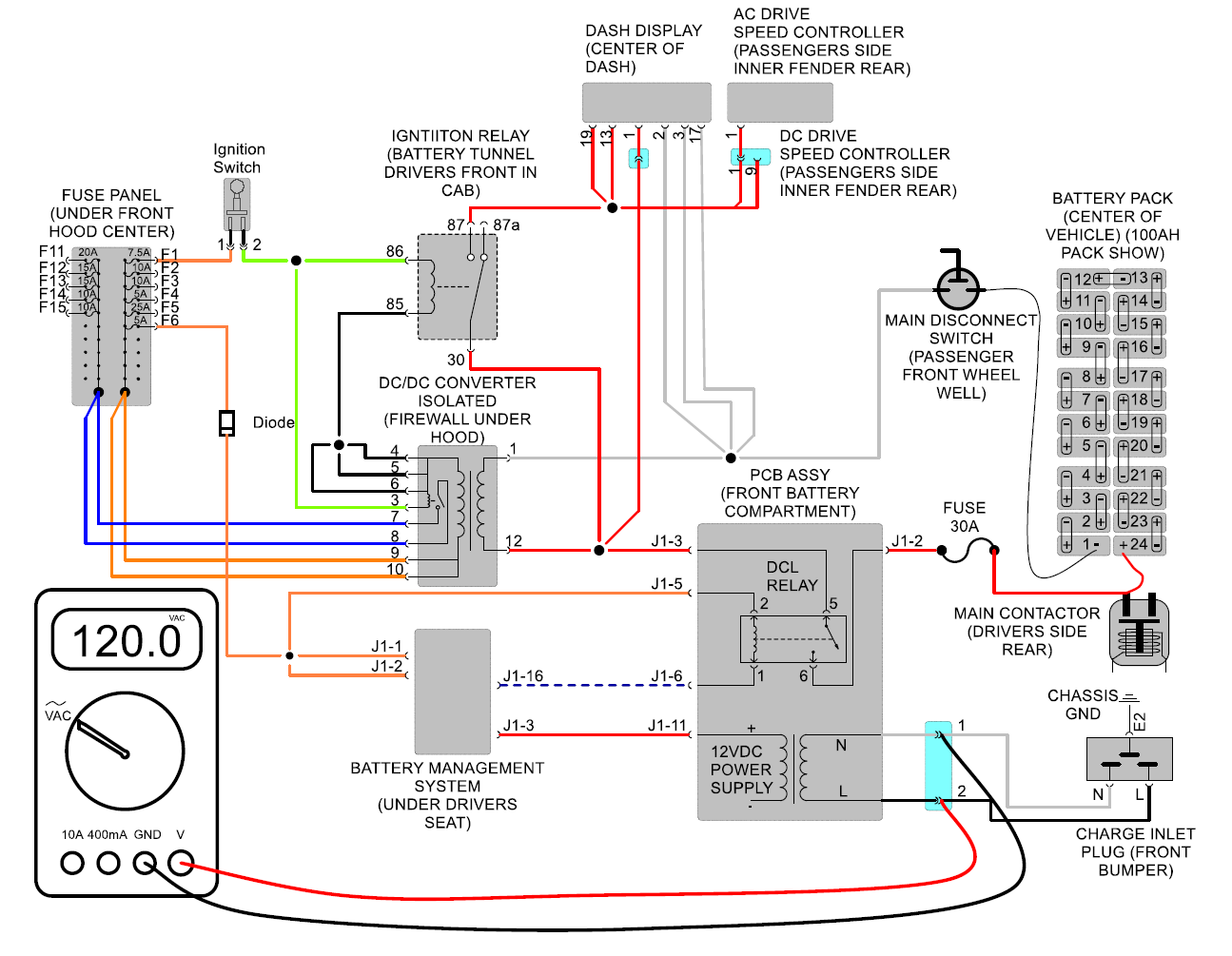

Test #1-2-3

Measure voltage between pin #1 and #2 of gray 4 pin connector if the pcb assy. Have

vehicle plugged in at the front bumper

like its charging. You should measure

the same AC voltage plugged into the front bumper 120VAC or

220VAC. If so the PCB assy is bad and needs to be

replaced.

If not then either you have no power at the front inlet plug, a wiring issue between the inlet and this gray connector or wiring/plug issue at the charge port in the front bumper.

Test #1-3

At the battery management system located under the drivers seat. Locate the

main I/O connector which is white and

has 26 pin locations. Measure

voltage between pin #3 and pin #4, 5 or 6 of DC/DC converter 12 pin

connector (Connector must be plugged in for this test) or any small black wire

at the 15 pin connector going to center

console. Have vehicle plugged in at the front bumper as if it were

charging. You should measure

about 12 volts DC.

If so, see test #1-4

If not, you have a wiring issue between the battery management system and pcb

assy.

Test #1-4

At the battery management system located under the driver's seat. Locate the

main I/O connector which is white

and has 26 pin locations. Measure voltage between pin #3 and pin #16.

Have vehicle plugged in at

the front bumper as if it were charging. Also, connector must remain

plugged into the BMS for

this test. You should

measure about 12 volts DC.

If so, see test #1-5

If not more than likely the battery management system has an internal fault the DCL relay will not close, and this fault must be corrected. In order to read fault code, you will require a computer and diagnostic cable part# U5665A-N.

If not more than likely the battery management system has an internal fault the DCL relay will not close, and this fault must be corrected. In order to read fault code, you will require a computer and diagnostic cable part# U5665A-N.

Test #1-5

At the lithium PCB assembly located at the front of the battery pack. Locate the

main I/O connector which is

black. Measure voltage between pin

#5 and pin #6. Have vehicle plugged in at the front bumper as if it were charging.

You

should measure about 12 volts

DC.

If not, you may have a connection issue between battery management system and pcb assy. but also see test #1-5-2.

If so, see test #1-6.

If not, you may have a connection issue between battery management system and pcb assy. but also see test #1-5-2.

If so, see test #1-6.

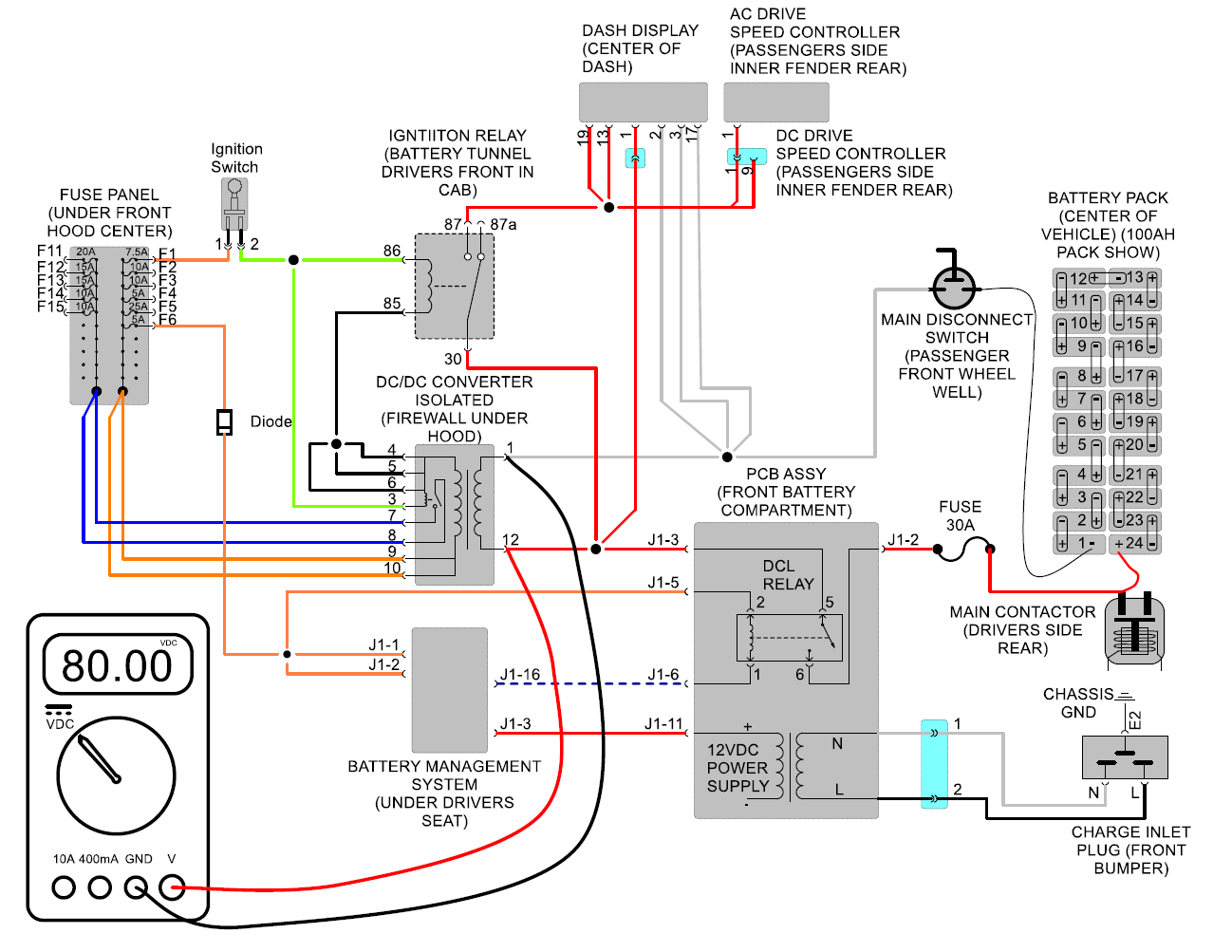

Test #1-5-2

Measure voltage between B- of main battery pack and pin #2 of black

connector at pcb assy. You should measure pack voltage

typically 80VDC.

If so, see test #1-5-3

If not see test # 1-5-2-2

Test #1-5-2-2

Measure voltage between B- of main battery pack and both sides of main 30-amp

fuse located in the driver's side rear of

vehicle. You should measure

pack voltage typically 80VDC on both sides.

If so, then you have a wiring issue between the fuse and pcb assy.

If you have power on one side, then fuse is blown replace and retest.

If no power on either side, then you have a connection issue between 30A fuse and

battery pack.

Test #1-5-3

Measure voltage between B- of main battery pack and pin #3 of black

connector at pcb assy. Connector must

remain plugged in for this test. You should measure pack voltage typically 80VDC.

If not, pcb assy is bad and needs to be replaced.

If so, you have a wiring issue between pcb assy and converter.

Test #1-6

At the lithium PCB assembly located at the front of the battery

pack. Locate the main I/O connector which is

black. Measure voltage

between pin #5 and pin #6. Have vehicle plugged in at the front bumper

as if it were

charging. You should measure about 12 volts DC.

If not, you may have a connection issue between battery management system.

and pcb assy. but also see test #1-5-2.

If so, see test #1-6.

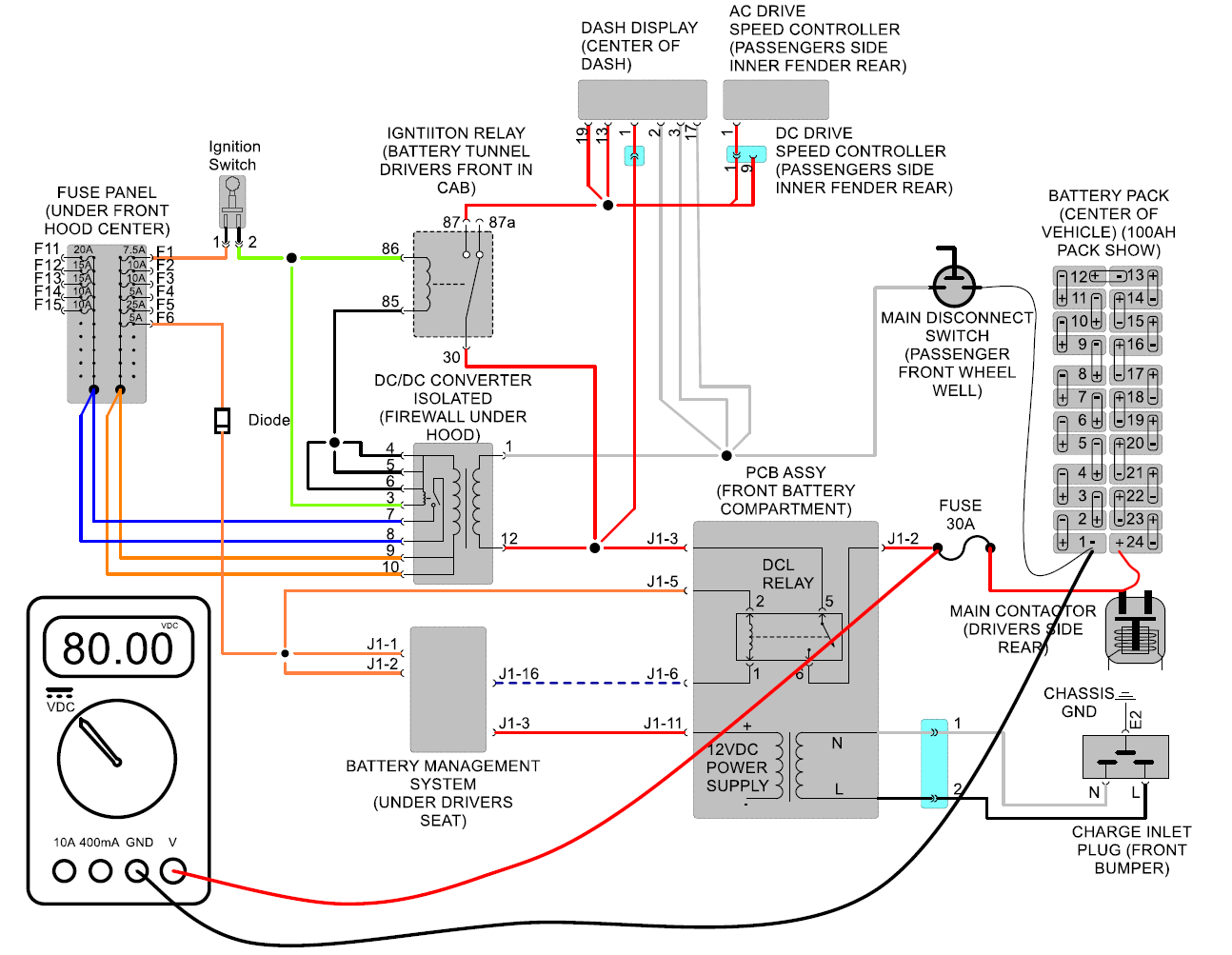

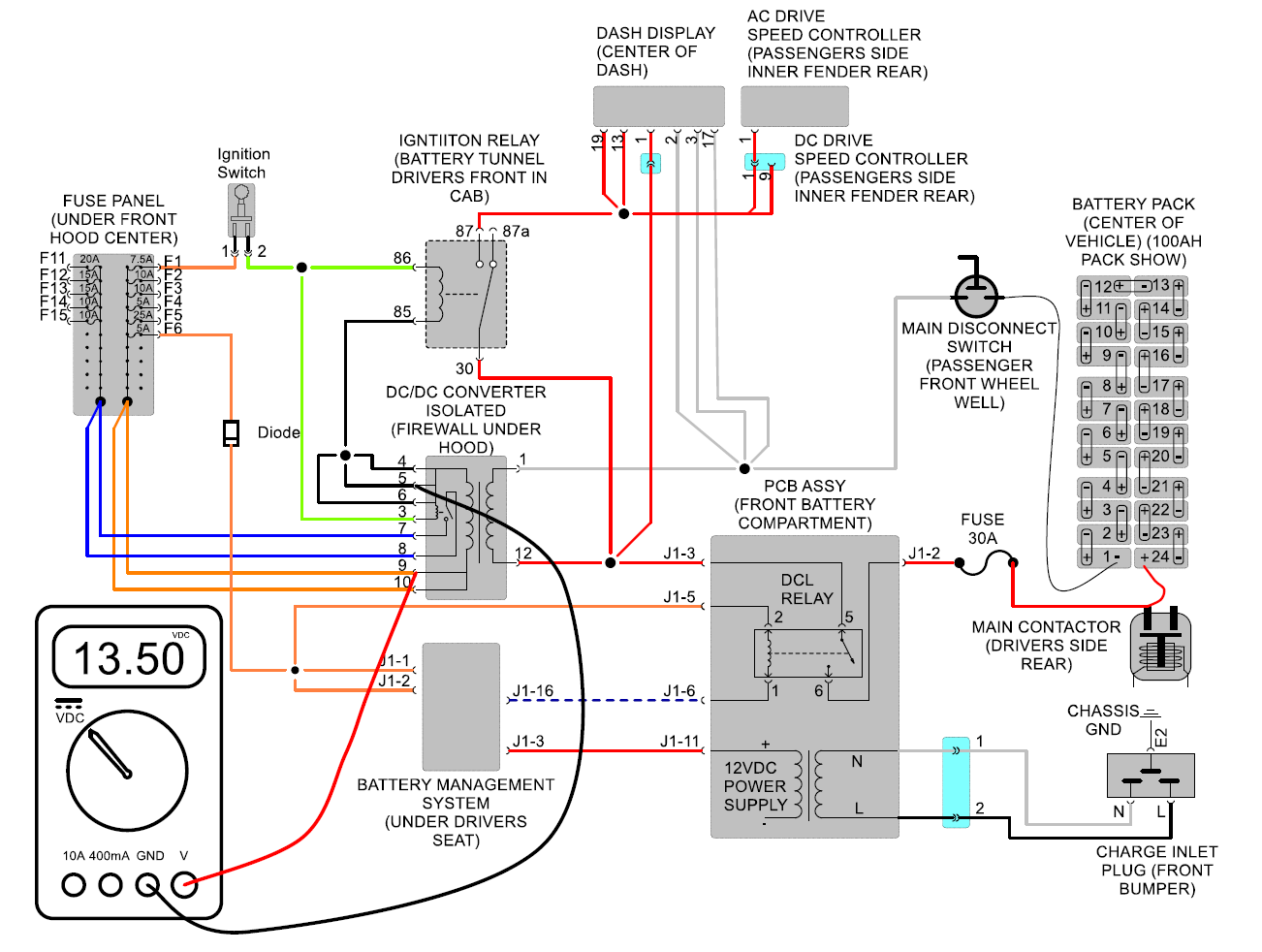

Test #2

Measure voltage between pin#4, 5 or 6 pin#9 or 10 of DC/DC

converter 12 pin connector. Connector must be

plugged in for this test. Should measure about 13.5 volts

DC.

If so, see test #3.

If not DC/DC converter is bad and needs to be replaced.

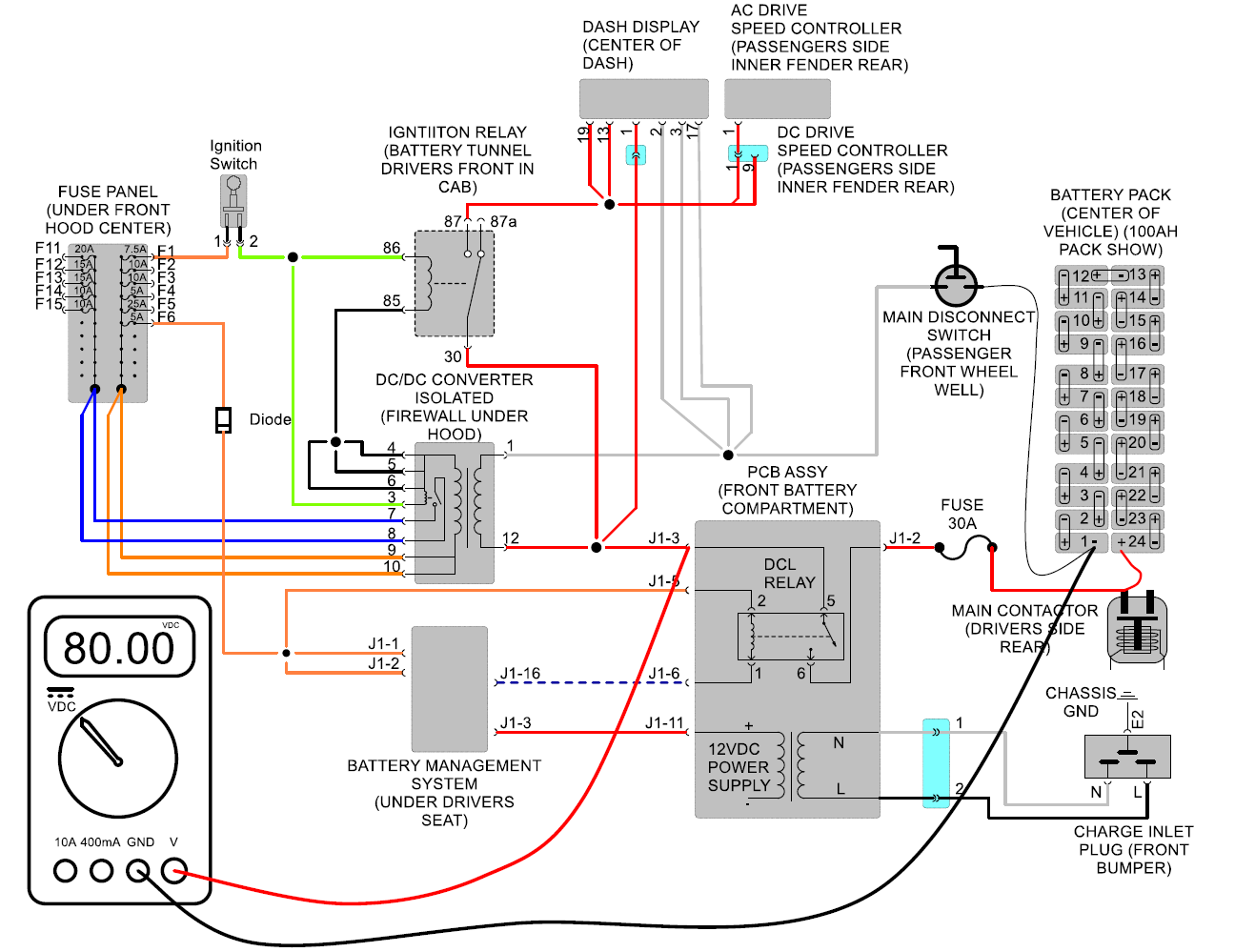

Test #3

Measure voltage between pins #4, 5 or 6 pin #3 of DC/DC

converter 12 pin

connector. Connector must be plugged in for this test. Ignition

key needs to be

in the on position. Should measure about 13.5 volts

DC.

If so, see test #4

If not see test #5

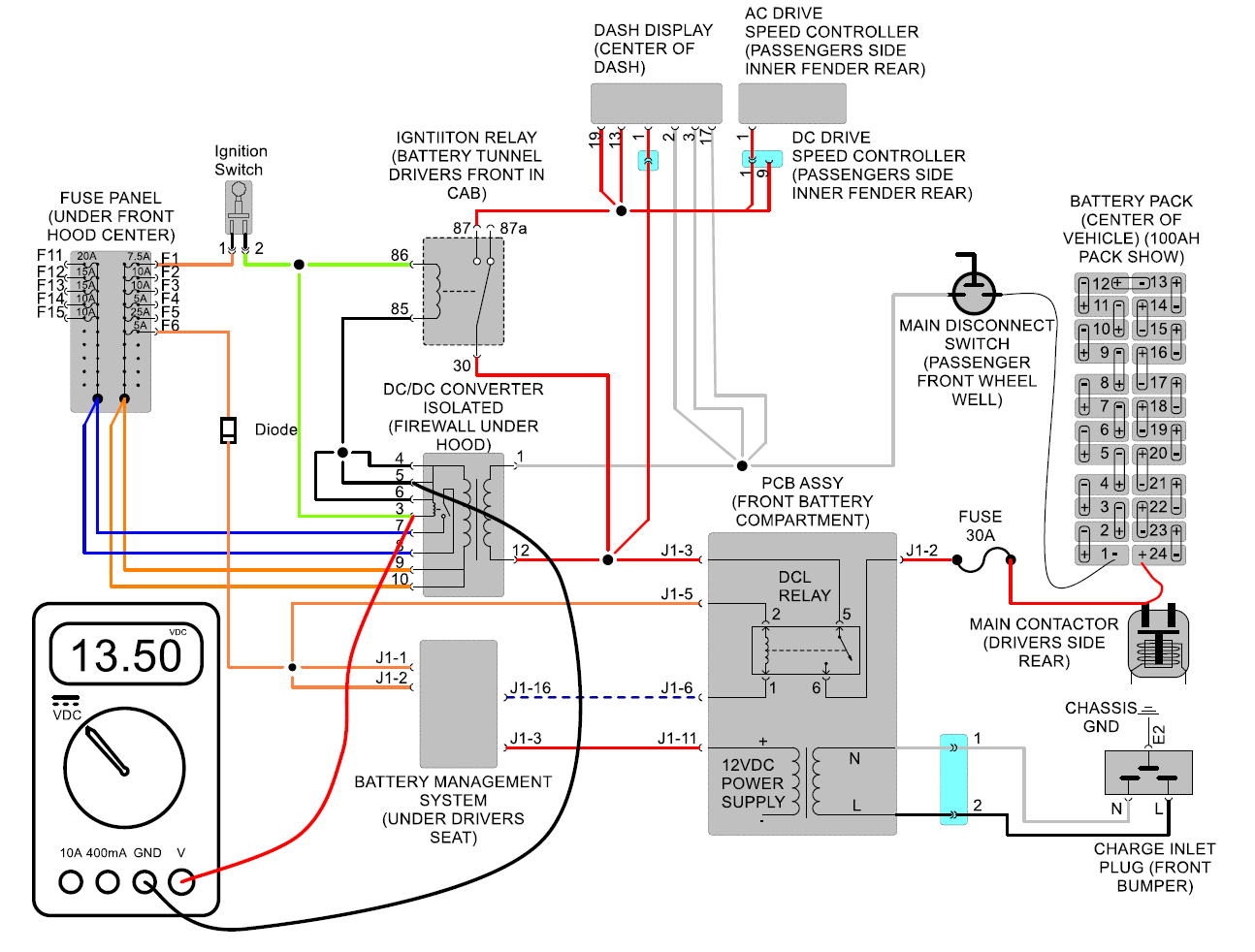

Test #4

Measure voltage between pin #4, 5 or 6 pin #7 or 8 of DC/DC

converter 12 pin connector. Connector must be

plugged in for this test. Ignition key needs to be in the on

position. Should

measure about 13.5 volts DC.

If so, DC/DC converter is bad and needs to

be replaced.

If not see test #5

Test #5

Measure voltage between pin #4, 5 or 6 of DC/DC converter 12

pin connector (Connector

must be plugged in for this test) and top of F1 fuse. Both

sides of fuse should measure

13.5 volts DC.

If only one side fuse is blown, try new good fuse and retest.

If neither side measure voltage, then you have a

wiring/connection issue in the fuse panel or between fuse

panel and DC/DC

converter.

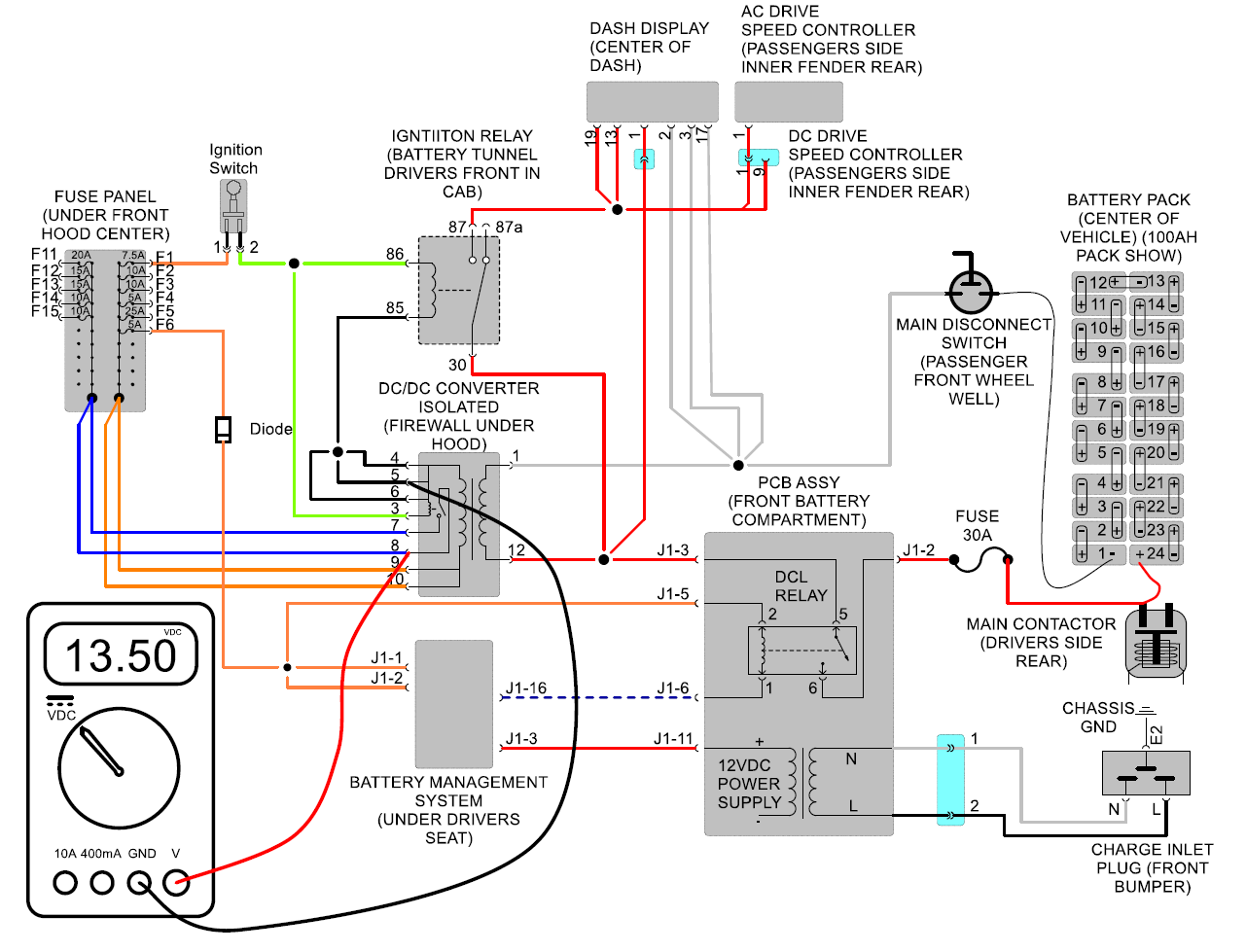

Test #6

Measure voltage between pin #4, 5 or 6 of DC/DC converter 12

pin connector (Connector must

be plugged in for this test) or any small black wire

at the 15-pin

connector going to center console and pin #1 of

ignition switch. Should measure 13.5 volts

DC.

If so, see test #7.

If not, you have a wiring issue between the ignition switch and F1 fuse

panel.

Test #7

Measure voltage between pin #4, 5 or 6 of DC/DC converter 12

pin connector

(Connector must be plugged in for this test) or any small

black wire at the 15-pin

connector going to center console and pin #2

of ignition switch with

ignition switch in the on position. Should measure

13.5

volts DC.

If so, see test #8.

If not, you have a bad ignition switch.

Test #8

Measure voltage between pin #4, 5 or 6 of DC/DC converter

12 pin connector

(Connector must be plugged in for this test) or any small

black wire at the

15-pin connector going to center console and pin #86

of ignition switch

relay with ignition switch in the on

position. Should measure

13.5 volts DC.

If so, see test #9.

If not, you have a wiring issue between ignition switch

and ignition switch relay.

Test #9

Measure voltage between B- of main battery pack and

pin #30 of ignition

switch relay Should

measure pack voltage typically about 80 volts.

If so, see test #10.

If not since test #1 tested good, then you would have

a wiring issue between the ignition relay and the wiring harness

splice.

Test #10

Measure voltage between B- of main battery pack

and pin #87 of ignition

switch relay with ignition switch in the on

position Should

measure pack voltage typically about 80 volts.

If so,

see test #11.

If not, ignition relay is bad and needs to be

replaced.

Test #11

Measure voltage between B- of main battery

pack or speed controller and pin #1 of speed controller

with ignition switch in the on

position Should

measure pack voltage typically about 80

volts.

If so and controller is not powered (no LED

lights) controller is bad and needs to be

replaced.

If not, you have a wiring issue between the

ignition relay and speed controller.